Overview

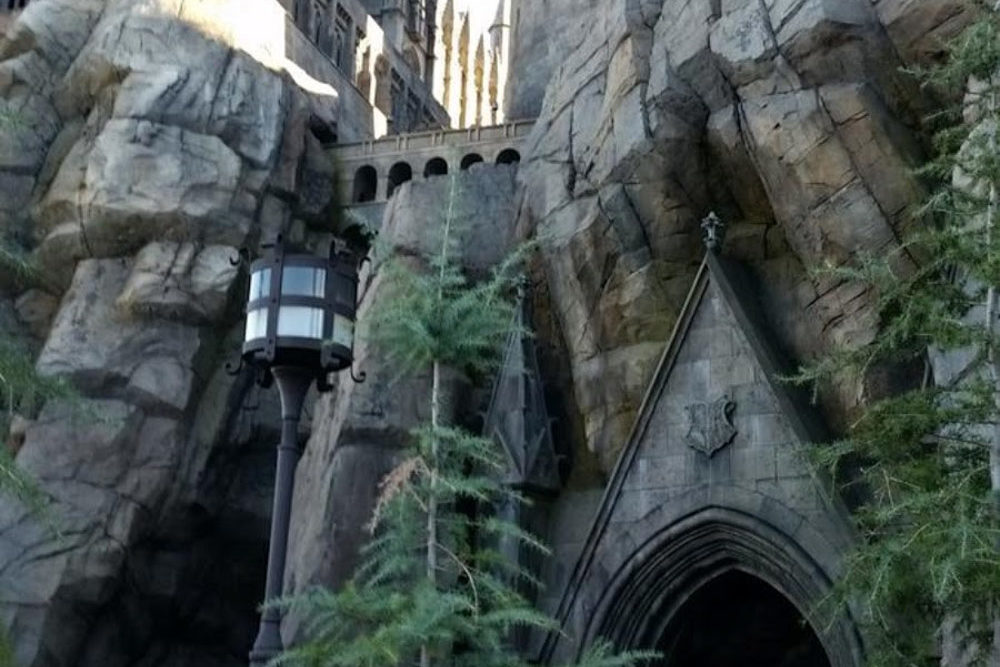

With the precision of master craftsmen, KHS&S used traditional and non-traditional methods to complete this magnificent project. Multiple buildings are meant to look aged, weathered and damaged; some to look over 300 years old! Building finishes had to to replicate worn and weathered stone, plaster, metals, and wood. With KHS&S master craftsmen, the unique facades were achieved using various finish techniques including plaster, EIFS, a myriad of paint & paint appliques and installing more than 30,000 elements consisting of real and faux wood, FRP, GFRC, millwork, windows and window treatments. The challenging aspect of the plaster were the various types of plaster finishes that not only tied into one another, but also tie into the FRP, wood, and themed elements.

KHS&S helped bring the project to life through the framing of straight, radius, angled and low walls, twisting and radius chimneys, roof trusses, dormers coming off of buildings at all angles, balconies, steel beam claddings, raised platforms along with barrel, vaulted and domed ceilings. With so much variation in framing, the project was anything but a typical framing job. In many instances, areas of framing needed to appear crooked or skewed to stay true to the replicated scene but also needed to be structurally sound.

Our outside the box thinking of prefabricating nearly 100 dormers off-site and shipping them to the job site for installation was made possible through the use of 400 LOD BIM modeling and 3D coordination. Any imperfections in fabrication and / or on-site framing would mean that the dormer would not fit and need to be field adjusted, delaying the project schedule and increasing costs. Prefabricating these dormers allowed KHS&S to proactively meet potential schedule impacts and not be affected by other trades. With the project consisting of 7 different structures, prefabrication allowed for schedule adjustment from building to building with minimal, if any downtime. KHS&S also prefabricated large-scale elements of the Hogwarts Castle, craning them into place to meet schedule demands. Prefabrication also gave KHS&S a higher quality product and increased job site safety since they were fabricated offsite in a controlled environment.

Prefabrication of 1,042 rockwork segments, known as “chips,” were used to create the ominous 42,250-square foot structure that the Hogwarts Castle sits on and all guests pass through to enter the motion ride Harry Potter and the Forbidden Journey™, which propels riders through additional prefabricated rockwork during their experience. KHS&S was responsible for the fabrication and installation of the “chips” along with required additional framing members and the carved plaster finish.

Services

- Preconstruction services

- BIM

- Framing & Drywall

- Plaster / Carved Plaster Finishes (wood planks/beams, rockwork, exterior stone)

- EIFs

- Paint and Paint Appliques

- GFRC

- FRP

- Windows and Window Treatments

- Millwork and Cabinetry

- Doors, Frames and Hardware

- Rockwork

- Structural Steel (for Rockwork)

AWARDS

- AWCI – Excellence in Construction Quality Award (2016)